Independent Research Confirms Highcon’s Non-Crush Creasing Delivers Stronger Boxes than Analog Die Cutting and Saves Manufacturing Costs and Trees

Yavne, 29 June 2022 – A peer reviewed scientific research paper published on June 25th in Sensors, an MDPI journal, found categorically that when compared to conventional creasing performed by flatbed analog die cutting, Highcon’s patented DART creasing technology better preserves the inherent mechanical properties of corrugated boards while sustaining high packaging quality.

The first-of-its-kind study examined the impact of analog and digital creasing lines on the performance of corrugated cardboard and finished boxes, conducted by researchers from the Institute of Structural Analysis, Poznan University of Technology and the Department of Biosystems Engineering, Poznan University of Life Sciences.

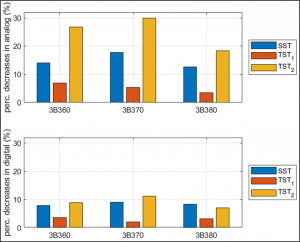

Researchers measured a broad range of parameters on boards creased by both an analog die cutter and a Highcon digital die cutting system. Measurements were made on areas of the board that were both creased and uncreased, as well as on complete boxes.

Key findings included:

Dvir Harmelech, VP R&D and Chief Technology Officer, Highcon comments: “In an era of rising costs, supply chain challenges and material shortages, we were delighted with the conclusion of the MDPI Journal report – it provides independent specialist confirmation for the benefits of our solution to help support these issues. More specifically, the ability to increase box strength, even with lighter boards, is key to unlocking important financial, operational, and environmental benefits. It not only helps producers of corrugated boxes to digitalize their production, but also to reduce the weight of their products and thus save more trees.”

The study can be found here

Showcasing Real Customer Jobs of Digital Die Cutting

Integrating Hybrid's renowned PACKZ software offering full PDF support

Discover the SEALED AIR® Korrvu® packaging produced with Highcon